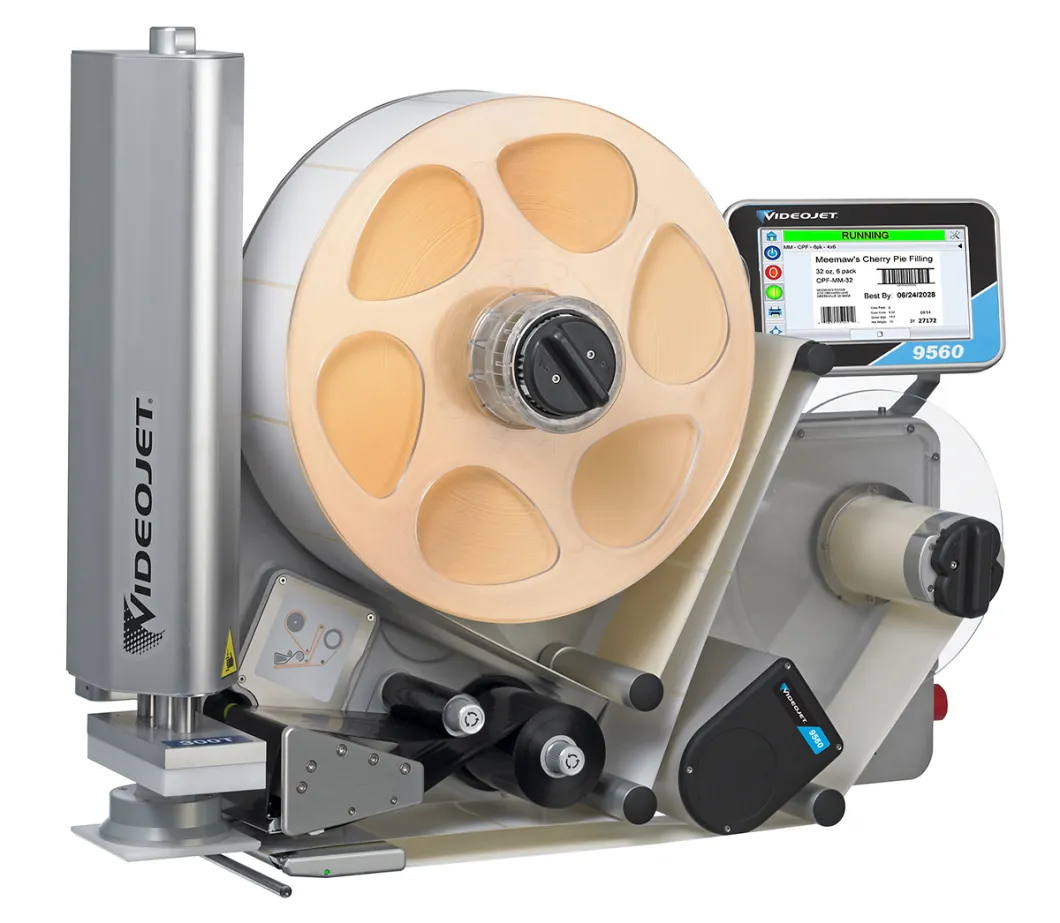

Specs

| Specification | Value |

| Application Method | Direct Apply (standard) with Intelligent Motion™ Label Drive Optional applicators: Front of Pack, Rear Corner Wrap, and Telescopic Tamp |

| Print Technology | Thermal Transfer printing with Intelligent Motion™ Ribbon Drive and Direct Thermal 53mm, 107mm, and 160mm printhead versions |

| Ribbon Width | Minimum 2.2” (55mm), 3.0” (76mm), 4.3” (110mm) (standard) and 6.4” (162mm) / Up to 830m |

| Print Resolution | 300dpi (200dpi in emulation mode) |

| Print Speed/ Throughput |

<4” label width up to 500mm/sec in standard mode and up to 750mm/sec in high speed mode >4” label width up to 400mm/sec in standard mode up to 150 packs/minute with a 4”x6” label dependent on label size and application |

| Emulations | ZPL, SBPL |

| Label Width/Length/Capacity | Width/length: 1.6” to 6.5” / 2.0” to 11.8” (40 to165mm / 50 to 300mm) Up to 400mm spool diameter (typically delivers over 9000 typical GS1 bar code labels per roll) |

| Interface | CLARiTY™ Controller with interactive on-board video tutorials |

| Connectivity | Ethernet, RS232, Configurable I/O (24V, PNP and volt free) and USB |

| Certification | CE and TÜV |