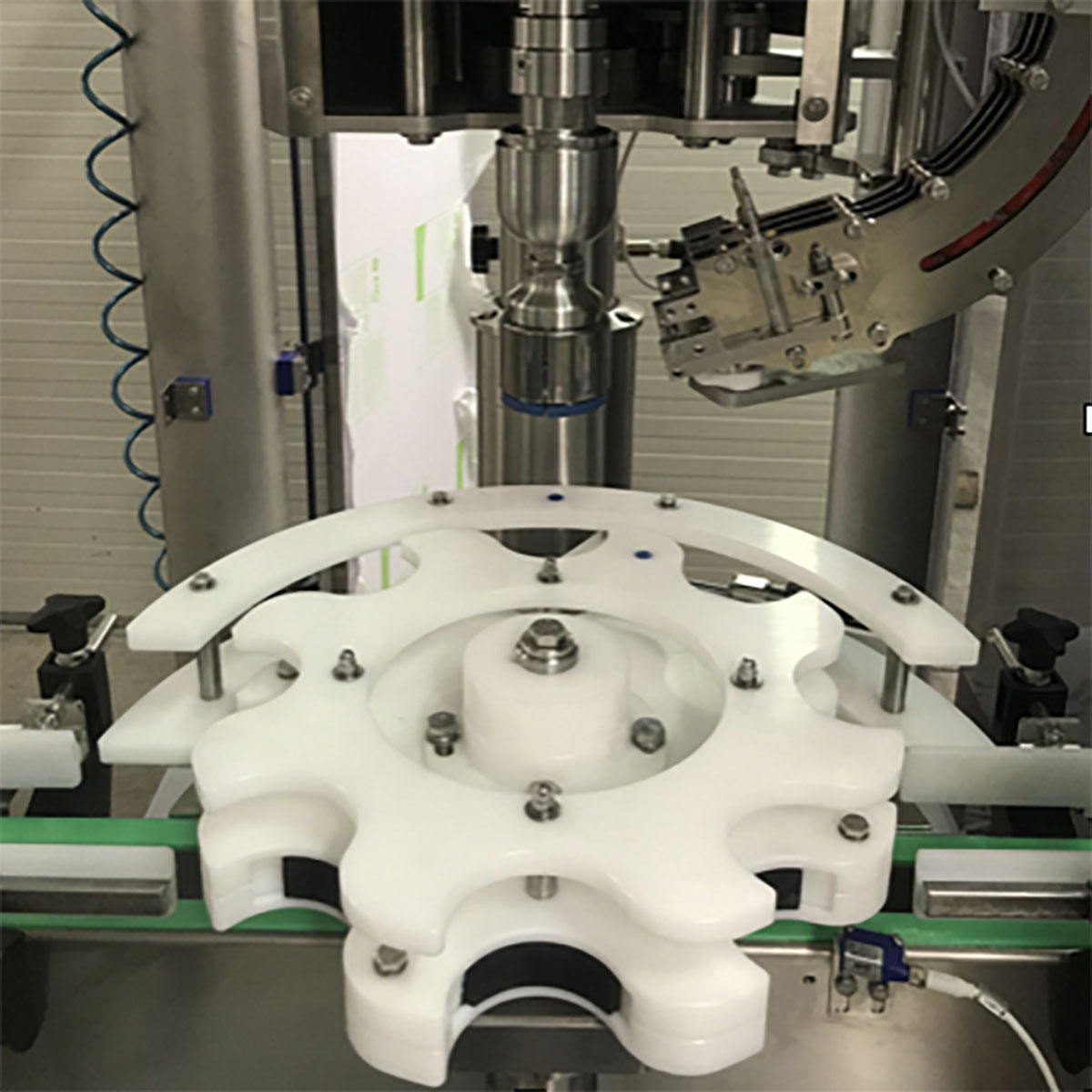

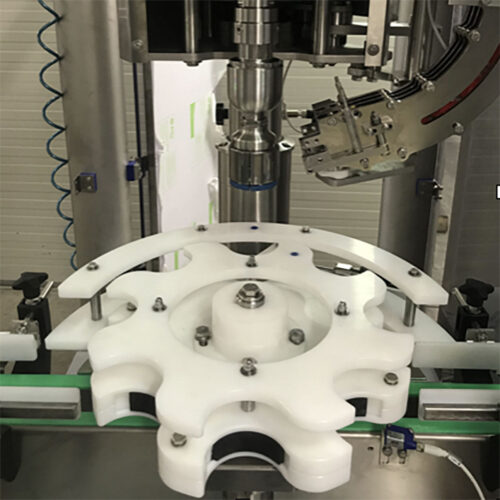

Why Choose Clutch Style Capping Heads

Clutch capping heads provide consistent and reliable capping without the fear of breakage, as with inline capping systems. It also allows a consistent and appropriate torque to be applied, ensuring a secure seal. With an inline capping system, there is no control of torque, which can cause inconsistencies in capping quality and potential breakage. ZimaPack builds Capping Machines with Pick & Place Devices, Dedicated/Flexible Capping Chutes and Torque Adjustable Capping Heads.

ZimaPack offers Clutch-Style Capping Heads. Why do we choose Clutch-Style Capping Heads? The answer is simple – because they provide a more accurate and reliable seal than other capping heads.

Types of Capping Heads

Our capping heads are the perfect way to seal your bottles quickly and precisely. We can build a Capping Machine to accommodate several different types of caps to promote versatility on your packaging line. Our experts can help you find the ideal capping head for your needs. We offer a solution for the following types of caps:

- Regular Flat Screw Caps

- ROPP Caps

- Press-On Caps

- Pump Caps

- Trigger Caps

- Flip-top Caps

- Sport and Push-pull Caps

- Dispenser Caps with or without pouring spouts

- Twist Caps

- Droppers (eye drops and dosing)

Our line of sorters for your capping needs

Sorters for cappers come in various designs, but they all essentially serve the same purpose: to make sure that the cap is being fed down the capping chute and to the pick & place device securely and in the correct orientation. This way the capping heads can do their job to apply the caps effectively onto the bottle/container. These are the kinds of sorters ZimaPack offers:

- Mechanical Sorter

- Centrifugal Sorter

- Waterfall Sorter

- Vibratory Sorter

Solutions Include:

- Rotary Cappers (Speeds above 25 CPM)

- Single-Head Cappers (Speeds up to 25 CPM)