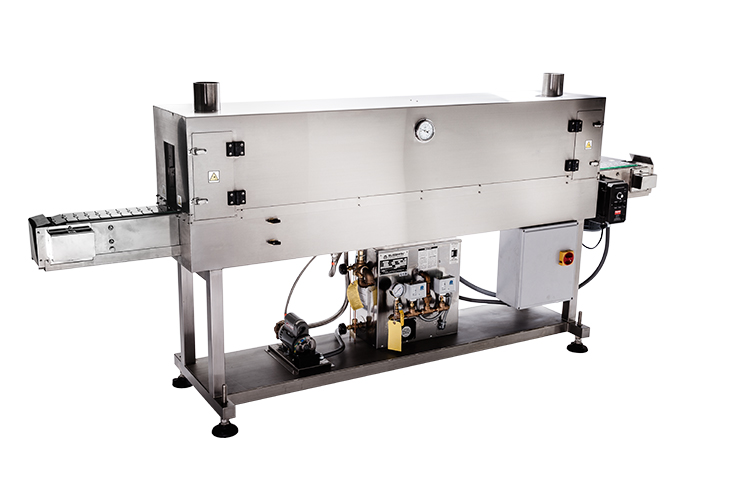

The WSN-GEN S Steam Heat Tunnel For Shrink Sleeve Labeling

The WSN-GEN S Steam Heat Tunnel for shrink sleeve label and tamper evident band applications from American Film & Machinery is designed for middle, full body, and full body and cap shrink applications. The WSN-GEN S is an all-in-one tunnel that includes its own steam generator. The tunnel is a perfect addition to shrink labeling lines in manufactured goods industries including food and beverage, pharmaceutical, nutraceutical, health and beauty, consumer goods, and chemical products.

Reliable Shrink Performance

The WSN-GEN S is designed for simple setup where in-plant steam generation isn’t readily available. Equipped with 2 adjustable tier manifolds, the The GEN S directs the steam heat where needed to produce a precise, high quality finished appearance of PVC, PETG, OPS, and PLA labels and neck bands. The GEN S provides better contour than radiant heat and ensures a quality finish regardless of container size or shape.

Designed to Perform

The GEN S tunnel utilizes a 9” tall and 4” wide opening to accommodate a number of shrink sleeve products. The tunnel has a maximum temperature of 212°F and features high quality steam heating elements and an adjustable manifold for uniform heat distribution. Changing containers or labels isn’t an issue – tier adjustments and controls are done from the operator side of the tunnel, making adjustments safe, quick and easy.

Technical Specs

TECHNICAL SPECIFICATIONS OF THE WSN-GEN S

- Machine Construction: Stainless steel frame and construction

- Zones & Tiers: 1 zone with 2 tiers

- Machine Dimensions: 3m (L) x 597mm (W) x 1372mm (H) 119” (L) x 23.5” (W) x 54” (H)

- Tunnel Dimensions: 2m (L) x 130mm (W) x 250mm (H) 78.7” (L) x 5.11” (W) x 9.84” (H)

- Maximum Product: Dimensions 228mm (H) x 101mm (W) 9” (H) x 4” (W)

- Conveyor Width: 117mm (4.5”) wide flat top chain conveyor

- Conveyor Length: 3m (118”) in length; optional extended length conveyor to accommodate shrink labeler

- Conveyor Height: 36” +/- 2”; includes casters and leveling feet

- Conveyor Speed: Variable speed conveyor to move product at rates up to 200/minute

- Boiler Specifications: 20KW electric boiler, 50 psi, internally plumbed, drip pan included for condensation recovery

- Maximum Temperature: 212° F