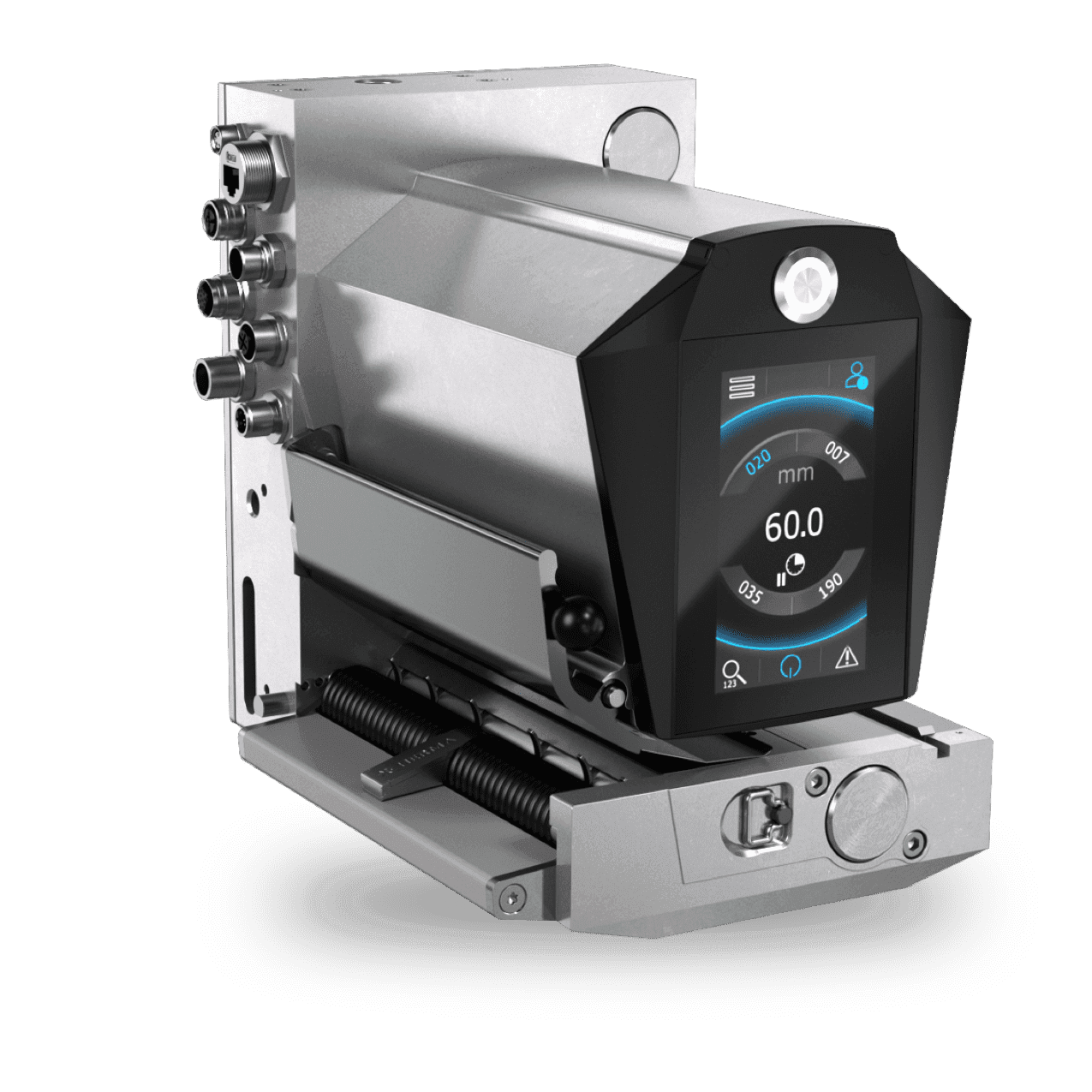

| Label Specifications |

| Label width: |

80 / 160 / 240 / 320 mm • 3.1″ / 6.3″ / 9.4″ / 12.6″ |

| Roll diameter: |

300 / 400 / 500 / 600 mm • 11.8″ / 15.7″ / 19.7″ / 23.6″ |

| HERMA 500 Technical Specifications |

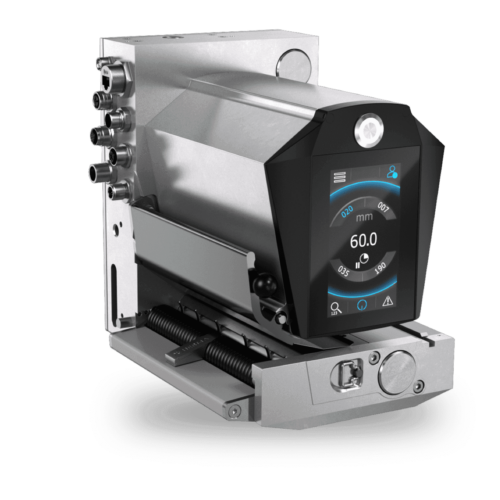

| Construction: |

Left-hand unit • right-hand unit |

| Labeling speed: |

0 – 30 / 50 / 80 / 150 / 200 m/min 0 – 98 / 164 / 262 / 492 / 656 ft/min |

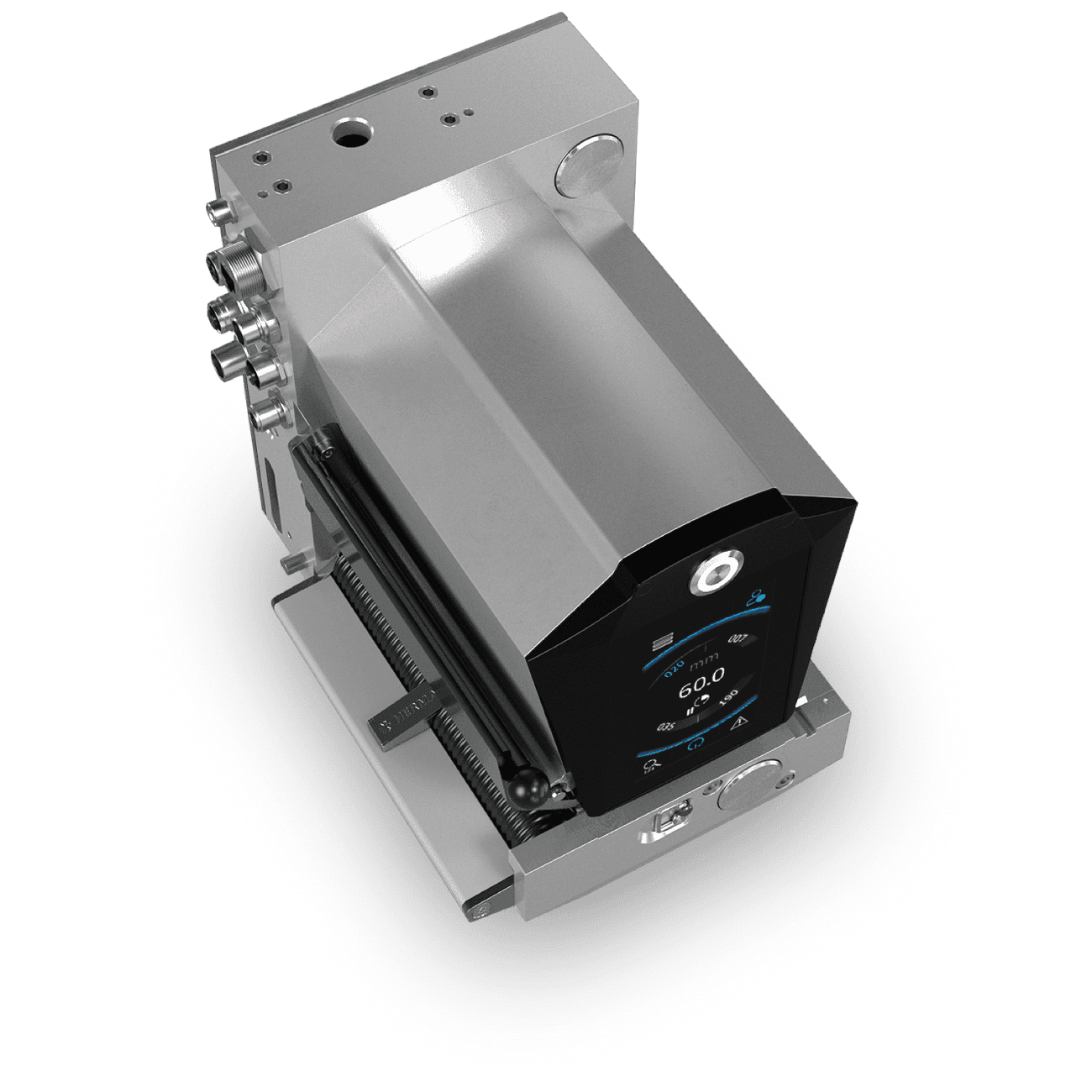

| Interfaces: |

I/O-Interface • Industrial Ethernet • Web Interface • OPC UA • CAN-Bus • master encoder • start signal • label scanning • printer • transfer system • Power Out |

| Labeling functions: |

Master encoder operation • machine control CAN-Bus |

| Certification: |

UL and CSA |

| Label scanning – Sensor type: |

Forked photoelectric sensor • FS03 for scanning of last label • ultrasonic sensor |

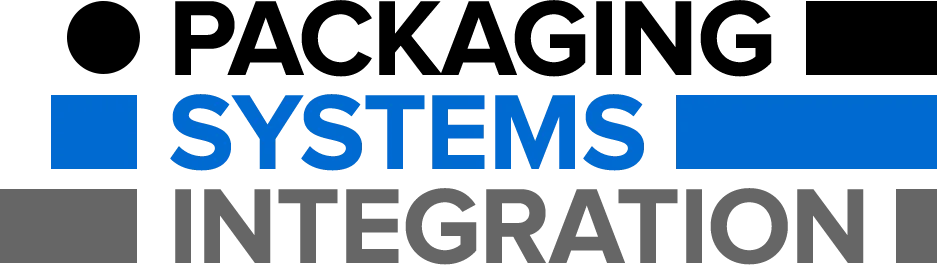

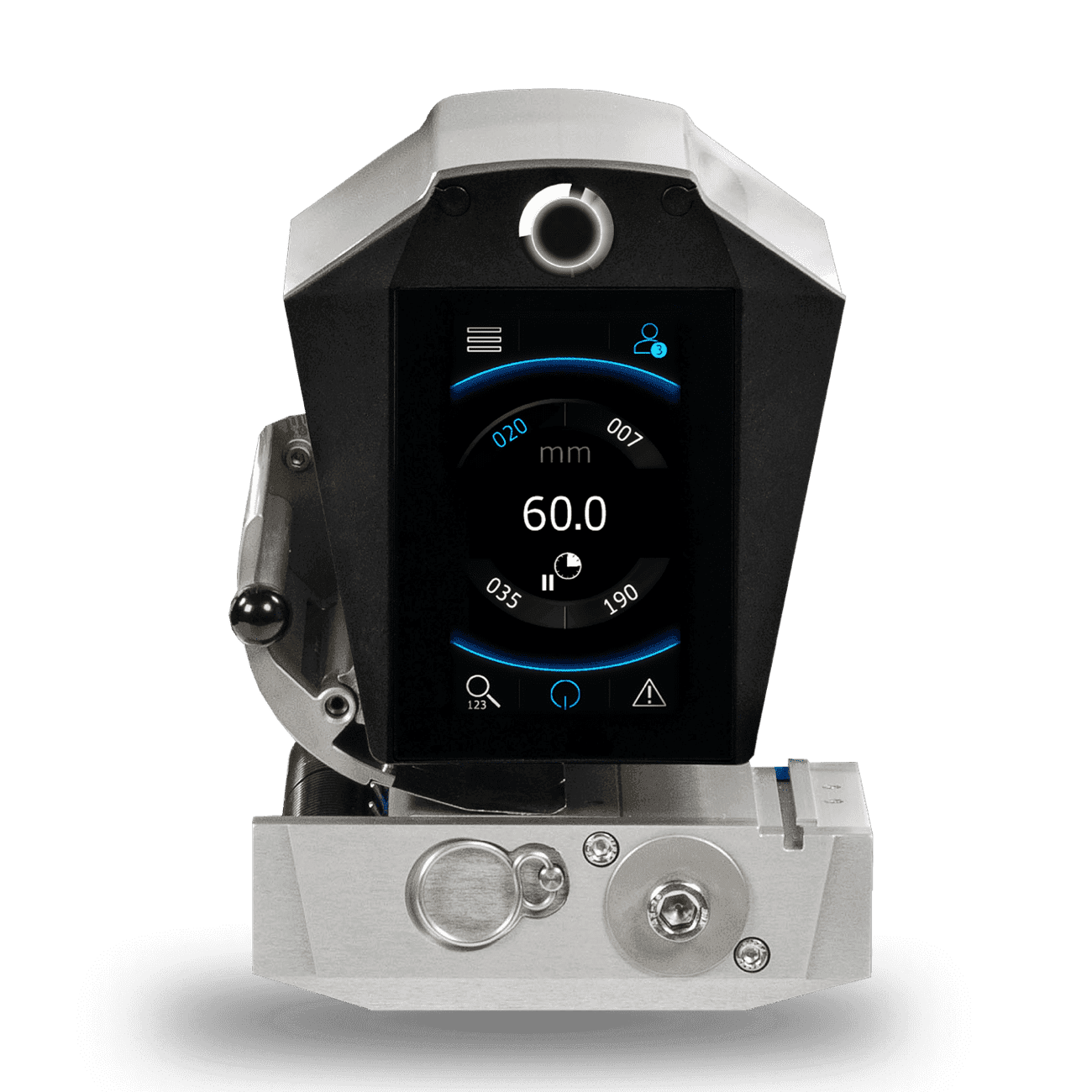

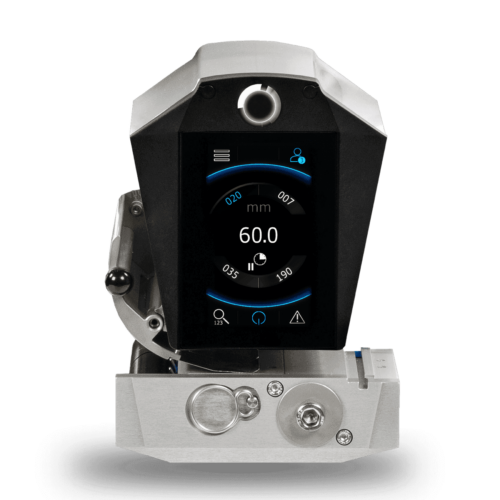

| Operation: |

Operation via pictograms on the 4.3″ color touchscreen • quick access to 4 parameters, menu, user administration, search, messages, operation on / off • format management • language selection • can be operated with gloves • button for manual label feed • main switch for complete mains isolation |

| Displays: |

Display rotatable in 90° steps • display of the configurable main parameter • status display: ready, alert, malfunction in various colors • display threading scheme • display operating manual |

| Service functions: |

Remote access via web browser • functional upgrade via code activation • firmware update via Ethernet TCP/IP |

| Drive technology: |

AC servo motor |

| Control technology: |

Fully integrated in the HERMA 500 |

| Power supply: |

100 – 240 V AC, 400 W, 50 – 60 Hz |

| Operating temperature: |

0 – 40° C • 32 – 104° F |

| Protection class: |

IP66 |